【 微信扫码 】

【 微信扫码 】

What is PPS?

The full name of polyphenylene sulfide is polyphenylene sulfide, also called polyphenylene sulfide (PPS). PPS is the most widely used special engineering plastics, known as the sixth largest engineering plastics. Its heat resistance, chemical resistance, flame retardant properties, mechanical properties, dimensional stability, excellent processing performance. With the enhancement of human's awareness of environmental protection and the pursuit of a healthy and comfortable living environment, PPS is more and more sought after by the market, and the market demand is increasing.

PPS has its excellent properties, thermal properties, electrical properties, chemical resistance, but also has disadvantages such as more flash during injection molding and poor product toughness. In order to solve these deficiencies, modification treatment can be carried out to develop high-performance PPS modified materials. Because PPS has good heat resistance, excellent mechanical properties, and good chemical stability and water resistance, PPS products are widely used in many fields.

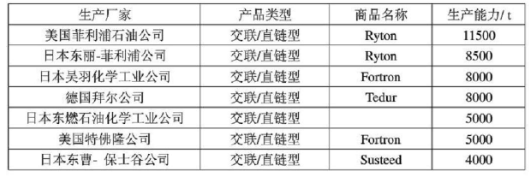

Status of foreign PPS production

According to the "2018-2022 Global and Chinese Market Polyphenylene Sulfide (PPS) Market Supply and Demand and Investment Opportunities" released by the Xinxinjie Industry Research Center, the world's major PPS manufacturers are Chevron. Phillips Chemicals Company, Japan Kureha Company, Japan Polytechnic Company, American Ticona Company, British ICI Company, German Evonik Company and other companies. Japan is a major producer of PPS, and its production capacity accounts for more than 50% of the world's production capacity; my country's PPS resin and modified composite materials use a huge amount of about 40,000 tons, accounting for half of the world's total.

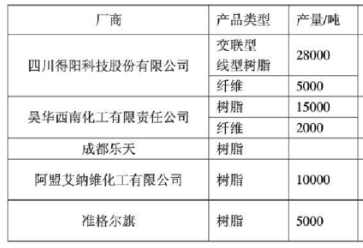

Domestic PPS production status

my country started PPS synthesis research as early as the 1970s; after the joint efforts of many predecessors, Sichuan Huatuo Technology Co., Ltd. first realized the industrialization of domestic PPS production in 2001, marking that my country has become one of the few countries in the world that produces PPS. one. However, due to the relevant technical blockade, domestic PPS production is not smooth, and the PPS resin required in the market depends on imports.

PPS needs analysis

According to the report, the global PPS consumption scale is expected to develop at a compound annual growth rate (CAGR) of 7.7% from 2016 to 2022, reaching 189,400 tons in 2022, reaching US$2 billion. The automotive consumption-based market share constitutes 41.5% and the largest application of PPS and is expected to maintain a CAGR of 6.6% from 2016 to 2022.

The amount of PPS resin and modified composite materials in my country is huge, about 40,000 tons, accounting for half of the world. Affected by the production suspension of Deyang Technology in China, the huge gap between supply and demand has led to a shortage of domestic engineering plastic grade and fiber grade PPS market; the second brand and nozzle materials are rampant, about 30,000 tons.

Automotive PPS Market Share Analysis

The automotive consumption-based market share constitutes 41.5% and the largest application of PPS, and is expected to maintain a CAGR of 6.6% from 2016 to 2022. However, the compound annual growth rate of industrial applications is the fastest growing at 11.2%, and the consumption is expected to be 59,700 tons in 2022.

BYD Automobile Industry Co., Ltd., which is the number one seller of new energy vehicles in China, is working on a lightweight project for standard battery packs. The project plans to use PPS resin instead of metal casings. At present, the company is conducting a comprehensive analysis in terms of cost, performance and reliability. By the end of 2017, BYD's total power battery production capacity was 16GWh. In 2017, China's power battery shipments were 44.5GWh, of which BYD's market accounted for 16%, ranking second.

PPS resin has broad development prospects in the field of new energy vehicles!