【 微信扫码 】

【 微信扫码 】

Lithium battery refers to a battery containing lithium in the electrochemical system. Due to the relatively active chemical properties of lithium metal, the environmental requirements for its processing are very high, which is also the reason why lithium batteries are not used on a large scale. With the advent of the information age, the microelectronics technology characterized by small size, light weight, high reliability and fast working speed has developed and expanded. With the increasing number of small and refined equipment, the requirements for batteries have also increased. , Lithium batteries have entered a stage of widespread practical use. Polyphenylene sulfide (PPS) has excellent heat resistance, insulation, electrical properties and other characteristics, which is in line with the requirements for materials in the field of lithium batteries, and is the "close companion" of lithium batteries.

Application of PPS in 21700 Battery PCAK

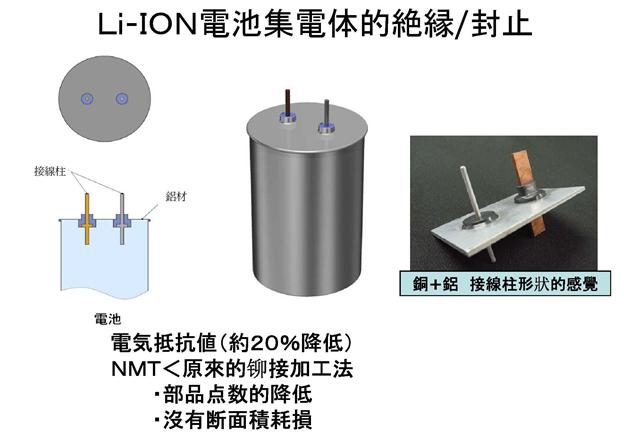

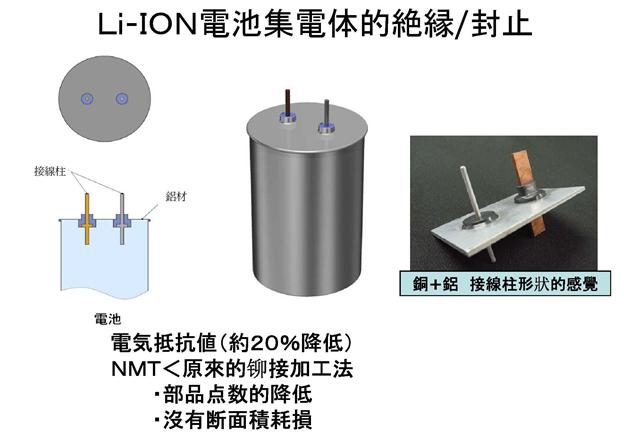

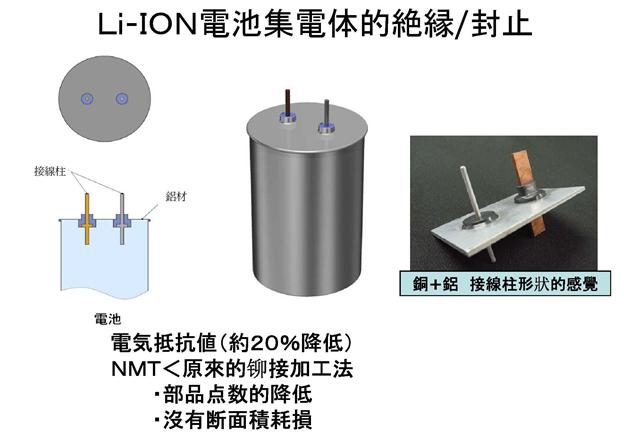

The application of PPS in the cover plate of new energy lithium battery is quite suitable. PPS has excellent electrolyte resistance and good bonding performance with aluminum poles and copper poles, making MIM nano-injection applied in power battery sealing rings, and it is the best choice for lithium battery sealing rings.

Compared with the traditional riveting process, the application of polyphenylene sulfide plastic in the NMT process of new energy batteries not only realizes the integration of metal and plastic structures, but also improves the metal texture and simplifies product components. , make the product light, thin and small, and more importantly, reduce the number of parts and reduce the loss of cross-sectional area.

PPS has the characteristics of high temperature resistance, low temperature resistance, dimensional stability, good insulation performance, and excellent battery thermal stress cycle. Adding an appropriate amount of barium sulfate can be used as a thermal insulation and shielding material for new energy vehicles.